Archive for January, 2017

Alum dedicates cyber security lab, study lounge

Monday, January 30th, 2017On January 27th, the College of Engineering dedicated the Paul A. Hotmer Family CSTAR Lab and study lounge. Mr. Hotmer’s contribution to the CSTAR Lab will fund cutting edge software and equipment. Through gaming and simulation, cyber security competitions, and other applications, engineering students will gain the skills they need to solve the challenges of tomorrow. Students might go on to preempt cyber attacks, aid national defense, or support forensic research, for instance.

Paul Hotmer is twice an alumnus of this college, graduating in 1955 with a bachelors in general engineering and 1961 with a masters in engineering. He then spent 40 years of his career as an employee of Owens-Illinois on the site that now houses the College of Engineering. He served the company as a technician and as a computer software manager. After retiring from OI, he continued to work as a software specialist at this location when Edison Industrial Systems took over the buildings now known as North Engineering and Palmer Hall.

Dr. Ahmad Javaid, Dr. Mansoor Alam, Paul Hotmer, and Interim Dean Steve LeBlanc at the dedication of the Paul A. Hotmer Family Study Lounge

Paul’s gift leaves a legacy both at his alma mater and at the physical site where his career unfolded. He worked for OI during a time of major technological innovation- he experienced the shift from manual drawings and manufacturing to computer-aided design and manufacturing. The extreme change he embraced in just a few decades illustrates the importance of preparing students both for current industry needs and for future technology expansion.

Speed school: UT students design race car from scratch

Monday, January 23rd, 2017

Often college means learning the nuts and bolts of life — sometimes literally.

University of Toledo Formula SAE members Dustin Moosman, left, and Josh Remmetler, right, push the team’s car from last season through the lobby of the North Engineering Building to take a group photo with the car.

Consider the University of Toledo, which for the past 20 years has participated in the Formula SAE program, where students engage in a “club” activity that allows them to create a Formula (open-wheeled) race car from scratch over two semesters.

Sponsored by the Society of Automotive Engineers, the program was launched to give students a taste of the full spectrum of the automotive industry. As detailed on SAE’s website, the concept is that a team is contracted by a fictional manufacturing company to design a Formula-style race car that will then be tested and evaluated at the yearly competition held at Michigan International Speedway in mid-May.

This means the UT team, also known as Toledo Motorsports, must start from scratch each fall, modeling every chassis tube and suspension component and perfecting the aerodynamics before driving their creation on the tarmac in seven month’s time.

“We like to say that we do about 90 percent of the car in-house,” said team lead Jacob Kennedy.

PHOTO GALLERY: Speed school at UT

A sophomore in the UT mechanical engineering program, Mr. Kennedy explained that the only components team members don’t fabricate are the ones they can’t; the wheels, the engine, and shocks must be purchased rather than created.

From September to May, the team uses modeling software, welding, machining, and more in a machine shop in the school’s North Engineering building.

Team members also learn about the economic side of the field. They are responsible for sourcing the materials, soliciting sponsorships, and getting funding for the parts.

Public speaking is also a factor. As part of the main competition, the team must defend its design to a panel of experienced judges in a pseudo-Shark Tank environment.

While the concepts and general practices of the competition and program remain fairly consistent, Toledo Motorsports decided to break from the mold for the current season. For the last few years, the team has been recycling a similar chassis design paired to a Honda CBR 600cc motorcycle engine. This year it made the decision to change the motor to a KTM 450cc single-cylinder engine, which has caused a shake-up in the entire design of the car.

A complete redesign might seem unorthodox for a team that placed 21st out of 120 teams in last year’s competition, but as Mr. Kennedy puts it, “The team has pretty much maxed out what we can do with that [old] engine. … It got to the point that we were trying to fix something that’s not broken or trying to redesign something that’s already been gone over and over again.”

As the new semester starts, Team Motorsports is just about at the halfway point. As team members return to campus, they must still finish assembling the chassis so that the rest of the components can be installed or even designed.

Mr. Kennedy and his teammates hope to have their car assembled in time to work out the bugs before taking it to MIS in May, when their competitive rubber will finally meet the road.

While Toledo Motorsports won’t race against other vehicles, the competition includes various timed and static (design) challenges.

UT club to compete in American College Cricket Nationals

Friday, January 20th, 2017By Staff

The UT Cricket Club is one of 24 teams that will play in the American College Cricket Nationals starting March 15 in Fort Lauderdale, Fla.

The UT Cricket Club showed off its second-place trophy from the 2016 American College Cricket Midwest Championship. Posing for the photo were, from left, Koushik Rajapandian, Mahesh Pillai, Raj Patel, Akshay Chawan, Govind Sharma, Balram Yadav, President Sharon L. Gaber, Mohammad Wadood Majid, Rajeev Reddy, Naveen Tripathi, Swapnil Jadhav, Raviraj Wala, Abhijeet Thakur, and Dr. Sammy Spann, assistant provost for international studies and programs.

The club advanced to the nationals by finishing second in the 2016 American College Cricket Midwest Championship, where the top 12 universities competed for the Midwest Region Gordon Gee Championship.

Under the captainship of Raj Patel, the UT Cricket Club defeated 2016 season champion Wayne State University in the semifinals and secured its place in the nationals. UT beat Wayne State in October at Lyon Oaks Cricket Field in Wixom, Mich.

With that win, the UT club became the new No. 2 team in the Midwest. League play for UT included facing Penn State University and Ryerson University.

The UT Cricket Club is one of 24 teams that will play in the American College Cricket Nationals starting March 15 in Fort Lauderdale, Fla.

“It was a dream come true for all the team to take UT to the national level in cricket. Beating Wayne State University was a very tough task as they are a pretty strong team and winners in the past,” said Yogendra Patil, right arm fast bowler and batsmen. “I am looking forward for the nationals in March. Me and the team will give 100 percent to bring home the trophy — #gorockets!”

Not only did UT finish as runners-up in the Midwest, the Player of the Series Award went to University alumnus Rohan Kapkar for his all-round performance, and Most Valuable Player was given to UT student Akshay Chawan, right arm fast bowler, batsman and secretary of the club.

“The UT Cricket Club is looking forward to competing and winning nationals in March,” Mohammad Wadood Majid, opening batsman and president of the club, said.

“We hope to bring the trophy to our very own Toledo,” Nitesh Ralhan, club coach, added.

“While others were dreaming of success, we woke up, practiced hard, and gave everything to achieve it,” Chawan said. “For me, it’s a dream to play in such a big tournament in the USA, but to win I never imagined. It’s impossible to explain what I felt at that moment — just very happy to win. Winning a national championship in Florida is the No. 1 target now.”

The team has been playing together for two years and set out to compete in big tournaments this year. UT students and recent alumni comprise the team. According to the American College Cricket Midwest Championship rules, two recent alumni are allowed to play.

People interested in watching a cricket match can find games at Beatty Park in Toledo; Lyon Oaks Cricket Field in Wixom, Mich.; and Murphy Park in Pontiac, Mich. Fan also can watch on Sony Six Live and ESPN.

Engineering professor co-authors paper on flexographic printing of electronic materials

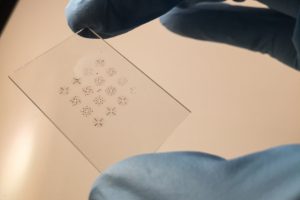

Monday, January 9th, 2017The printing of electronic devices provides inexpensive solutions for diverse applications. But precision on a nanoparticle scale limits the success of sensors and transistors that are electronically printed. Dr. Hossein Sojoudi, Assistant Professor in the Department of Mechanical, Industrial, and Manufacturing Engineering, helped to engineer a solution: nanoporous microstructures that will serve as a next-generation stamp material, comprising polymer-coated aligned carbon nanotubes (CNTs). A paper on this new technology was recently published in Science Advances.

Since its invention in ancient times, relief printing, commonly called flexography, has been used to mass-produce artifacts ranging from decorative graphics to printed media. At present, higher resolution flexography is essential to manufacturing of low-cost, large-area printed electronics. However, due to contact-mediated liquid instabilities and spreading, the resolution of flexographic printing using elastomeric stamps is limited to 50-100 µm. “We designed and engineered the highly porous CNT microstructures to be wetted by colloidal inks, and to transfer a thin layer to a target substrate upon brief mechanical contact. This enabled printing of diverse micron-scale patterns of a variety of functional nanoparticle inks onto both rigid and compliant substrates,” Sojoudi said.

Sojoudi’s role in the research was to develop ultrathin polymer coatings to control elasticity and wettability of the porous CNT microstructures, using initiated chemical vapor deposition (iCVD).

“With a 30 nm thick polymer coating, we were able to prevent aggregation and shrinkage of the porous microstructures,” he said. “In addition to having micrometer-scale resolution, the direct printing of patterns with uniform nanoscale thickness is greatly beneficial to scalable manufacturing of devices such as high-performance transistors and low-cost wireless sensors.”

Dr. Sojoudi helped fabricate a stamp made from carbon nanotubes that is able to print electronic inks onto rigid and flexible surfaces. Photo credit: Sanha Kim and Dhanushkodi Mariappan

The project was led by Dr. Sanha Kim, a postdoctoral fellow in Dr. A. John Hart’s research group, in collaboration with other research groups at Massachusetts Institute of Technology. Dr. Sojoudi was part of the research team while conducting his postdoctoral research with Prof. Gareth H. McKinley and Prof. Karen K. Gleason at MIT, before joining UT in August 2016.

This research news has been shared widely. Read more here:

MIT News:

http://news.mit.edu/2016/stamping-technique-printable-electronics-1207

Eurek Alert, The Global Source for Science News:

https://www.eurekalert.org/pub_releases/2016-12/miot-stc120516.php

OOYUZ beta:

http://www.ooyuz.com/geturl?aid=14184497

Sci Feeds:

https://scifeeds.com/news/printable-electronics/

Search for the Good:

http://searchforthegood.com/printable-electronics-mit-news/

Nanotechnology Innovation: